(585)775-5289

ROBOTICS EXPERIENCE

FIRST Robotics Team # 3015

I was a member of the Spencerport Ranger Robotics Team for four years and continue to volunteer as a team mentor. In my senior year of high school, I served as the "Upper Mechanical Sub-Team Leader". My role was to manage the design and construction of the game-playing elements of the robot. We created one of the best robots in the competition and earned the opportunity to compete at the FIRST Robotics World Championship, where we won second place.

2017

For my senior season, I was selected to be the Upper Mechanical Subteam Leader and my role in individual elements was reduced so that I could focus on the overall design. I spent the first half of the season keeping the designs of each mechanism on track and ensuring proper integration between them. Unfortunately, halfway through the season it became clear that one of the scoring mechanisms - which was vital to our strategy - wasn't going to work. The device picked up large gears and placed them on a spoke. The space allocated to it was insufficient and the promising prototype wasn't getting better. I stepped in and designed a new mechanism as fast as I could.

Usually, mechanisms go through a few iterations before any parts are machined. But due to the extreme time crunch, some components were laser-cut before the surrounding parts were designed... which was stressful! Thankfully, the mechanism worked perfectly.

2016

I did not have much time to CAD in 2016 so the majority of my season was spent designing mechanisms and finishing ideas that the team selected. My particular skills at the time lent themselves to bringing plans from rough sketches to fruition as tangible objects through machining, CNCing or printing.

2015

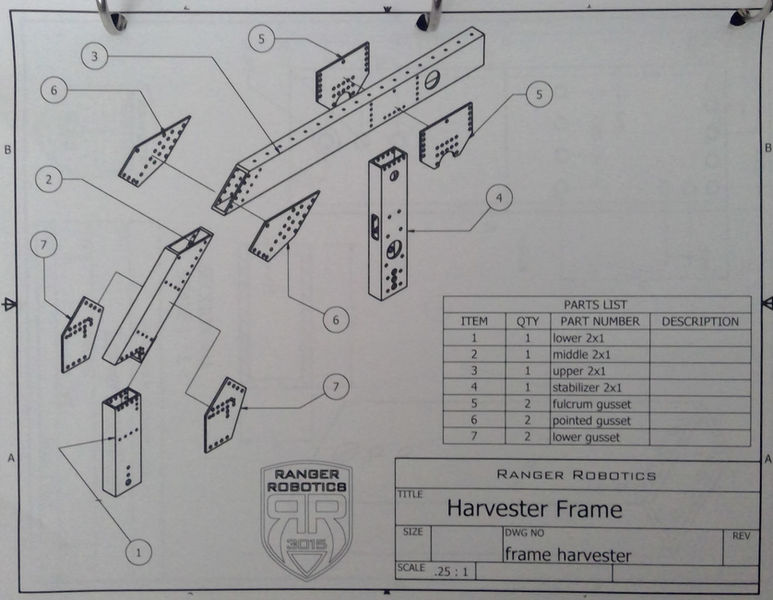

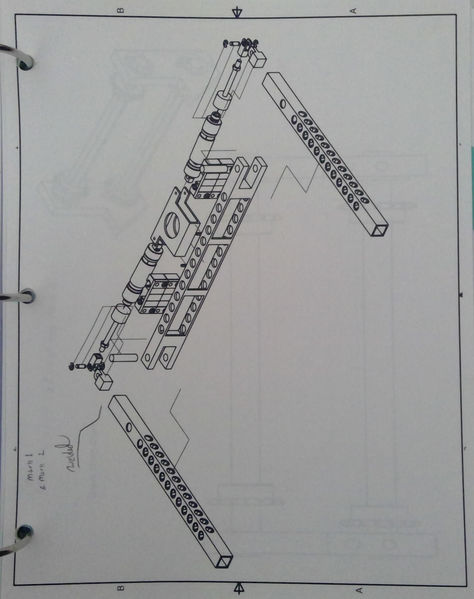

I joined the Spencerport Ranger Robotics team in 2014, but I did not have a substantial impact on design until the 2015 season. The game involved lifting trash cans and shipping containers, and my role was mechanical design, Followed by creating the whole robot in CAD. The majority of the parts were made without documentation and needed print-like part redrawing.